Best box of parts to ever grace my work bench.

Tweaking the 128×32 LEDDMD Verilog

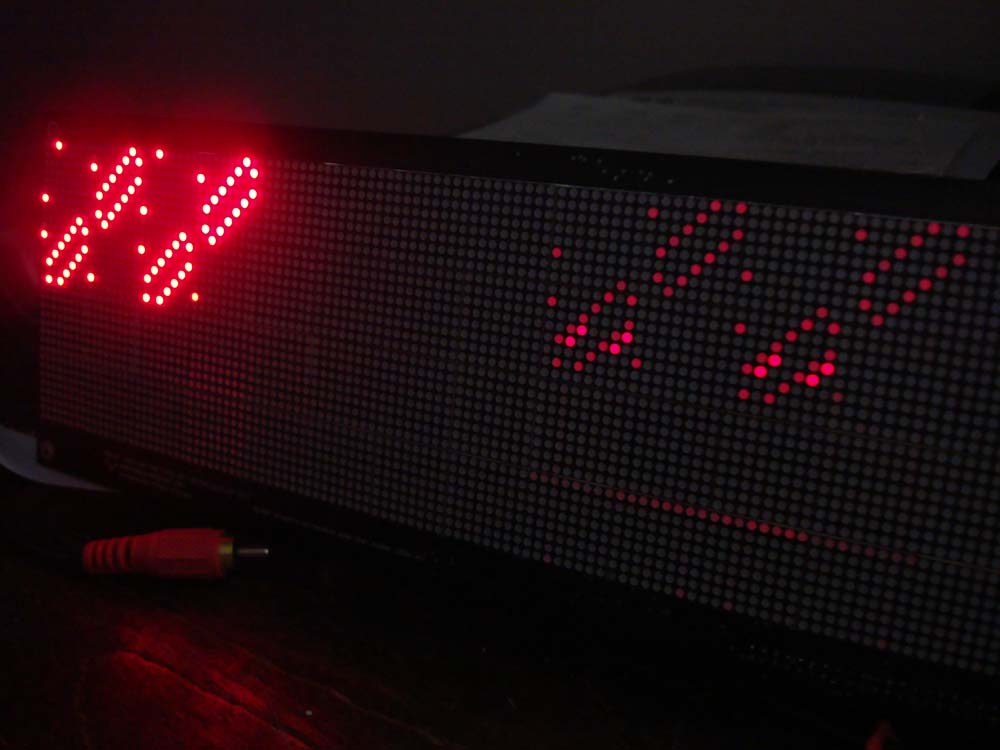

There was a few problems with the code for the 128×32 LEDDMD. Every so often there was flickering at random spots on the screen. This was because of the way the display memory was updated. I already fixed it by putting a dummy state at the end of the display memory update. Doing so actually increased the speed that data could be sent to the FPGA. There is no waiting between the Latch pulls.

The last problem is that there is some slight ghosting on the screen. Due to the way the screen updates it looks like the Column data is updating slightly before the rows are updated. Because of this you get a ghost effect on the opposite side of the screen that is up one row.

I think the reason why is because there is a slight delay in the rows caused by the decoders. The current plan of attack is to buffer the Column data a couple cycles before outputting.

LEDDMD 128×32 Complete

So I finally finished the prototype of the 128 x 32 Light Emitting Diode Dot Matrix Display V1.0 (LEDDMD). The protocol to write to the display is almost exactly like a shift register. There is a clock, latch, and data lines. It works in either 1 bit mode or 8 bit mode data line modes.

In 1 bit mode there is only 1 data line and in 8 bit mode this is 8 data lines. 8 bit mode enables you to clock in an entire byte of data at a time speeding up the transfer process by a factor of 8. In either mode you can do animations smoothly. All processing of the data is done on the microcontroller. The Display stores the data and takes care of running the display.

The bulk of the hardware is in the FPGA. I am using a Cyclone II EP2C8Q208C8N FPGA breakout board. There are some darlington transistor arrays that sink the current from a single row. To expand the I/O of the FPGA some decoders are used.

Here are the links to all the code:

FPGA:

Main Routine

Memory

Propeller:

Transmission Protocol and Test

LM3S1968: 74HCT595 Shift Registers

For one of my up coming Labs for EE445L I am going to need to expand the I/O of the LM3S1968. I am using the 74HCT595 much like on my pinball machine. One 74HCT595 allows you to turn 3 output pins into 8 output pins. They can be daisy chained so you can have any multiple of 8 output pins for those 3 original output pins.

In this demo I have 3 74HCT595 chips wired up. Instead of using the SSIO ports on the LM3S1968 I bit banged the port. SSIO is built in hardware that does serial communication. I decided to not use is for the 74HCT595’s because I am going to use it in controlling a DAC.

The code is fairly module and easy to change to different ports and pins.

Link to the code.

Thermistors…Linear? How to make them so.

In my last video I showed off Lab 7 for EE445L which was the digital thermometer. To measure the temperature I used a thermistor which is a resistor that changes resistance based on the temperature.

These are non linear devices which make it a pain to get accurate readings directly.

More information on Thermistors: http://en.wikipedia.org/wiki/Thermistor

EE445L : Lab 7 Temperature Data Acquisition System

I am taking a class called EE445L which is microcontroller applications. It is a mainly lab based class where we design and prototype a new embedded system every week. We are using the Texas Instruments LM3S1968 Evaluation Board. The microcontroller is a ARM Cortex M3. It has an on board OLED display and a USB debugger. It is a fairly impressive piece of kit.

This is Lab 7 which is a Digital Thermometer. I can not post the code or schematics due to this being a Lab and it would be looked upon as academic dishonesty.

Lab 7 Problem Statement.

The Thermistor is a non linear device. That is as temperature increases linearly the resistance across does not scale linearly. Part of the circuit involves a resistor “bridge” this is a non linear setup. If you combine two non linear systems you can roughly get a linear system. It is not perfect but it is close enough.

After the bridge part the voltage level goes into an amplifier which boosts the signal to a level that the LM3S1968 can read via its ADC (Analog to Digital Convertor) ports. This signal is the passed through a Low Pass filter. The filter is set to cut off at 10Hz. The LM3S1968 is configured to sample at 100Hz. The signal is low passed to prevent aliasing from high frequencies which would cause interesting glitches on the ADC.

I will be recording all the major EE445L labs in the next coming days.

MSP-430: IEEE CS Competition – Knock Knock Security System

Matt and I won a TI sponsored Launchpad programming contest that was held by the IEEE CS here at The University of Texas at Austin.

Here is the link for the details. In case the IEEE site goes down here is a screen cap of the page.

The idea was to create a simple secret knock security system that could record a knock “pattern” and then only unlock a door when the pattern was repeated. Only three hours where given for the competition and we where the only ones to finish everything in that time slot. They extended the contest another hour to permit more teams to finish. More details about the contest can be had by downloading the packet they gave us.

Code

The code is a bit rough around the edges and the bulk of the program happens in the timer interrupt (which is a no no) but for only 3 hours to solve, design, program, and debug a solution; sloppy code is a bit expected.

Points where awarded based on a few areas.

Points:

Your solution will be graded and scored on the following categorizes

1) Time it took for your team to create the solution and produce a working

prototype to the Company.

a. Every 1 min is -1 pts

b. Ex: if you finish in 1:30 in you will get -90 points

2) Working prototype: after you submit your prototype to the company,

Quality Control will take it into their lab and run test on your system. Their

test will not exceed the specified requirements and each test you pass you

will get +10 points to your score. (MAX 80pts)

3) Documentation: As in any real project you should keep a good record on

how you came up with your idea for your solution. This is to keep the

company safe from legal problems, have a record of our intellectual

property.

a. Submit your code

b. Submit any notes

c. Document any resources for the internet

d. Instruction Manual

Our legal team at the company will take a look over and award points

(MAX 10pts)

4) Creativeness of the solution: When you submit your solution to the

company, your manager will take a peek at your solution. If you solved it in

a new and ‘creative’ way, this many include additional functionality, more

efficient algorithms, or intuitive (easy to use) interface. (MAX 30pts)

5) Cost: The Company does have a parts store. You will be able to buy extra

parts such as button kits and if you burn out your chip you can buy a new

one.

Help:

If you get stuck we do have an internal consulting group which will help you but

for a cost of 2pts per 1 min. This is not for questions about the contest or

questions about the problem; this is for help solving the problem.

We scored 65 points where the nearest team behind us only scored 22 points. We dominated the competition. The judges loved the simple interface and the admin password setup. The code was fairly changeable so you can adjust the precision of the knock (humans are not robots) and how long the passwords are. Teams that did finish had no where near the feature set our solution had.

First set done!

First 8 PDS V1.1 are built!

2 Prototype PDS V1.1 Left!

I only have 2 out of the 10 left from the initial run of V1.1. The first batch for those that have already ordered will be shipping this Friday. PDS V1.2 already has some design changes that will increase the boards functionality and usefulness even more without adding to the cost of the final product.

If you want to grab a the PDS V1.1 for testing send me an email. Cost is $25+$3 shipping which is the at cost price to make the PDS in low quantities.

V1.2 will hopefully be the full production version and will retail at $40ish.

Have a suggestion or want to discuss the PDS? Join our forums!

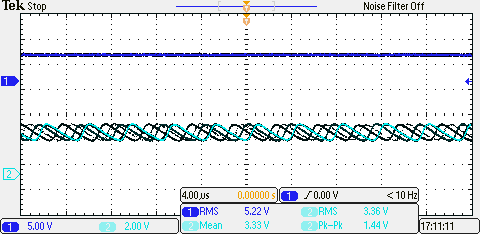

Power line noise analysis for the PDS V1.1

Here is some analysis of the power lines and noise on the board. These measurements are taken with no load on the I/O besides what is built in on the board. Pins 29 and 28 run the EEPROM in I2C mode on boot to load the program into the Propeller.

With the Propeller doing nothing the board takes 7mA on the 5V line. Flipping all the ports as fast as the Propeller can do it at takes 20mA at 5V. Turning on all the cogs (8) and flipping the pins takes 94mA which is almost 1/5th the power budget of the USB spec (5V 500mA). During these measurements the board was powered with a dedicated lab power supply.

Here is the worst case noise analysis of the board. This is when all cogs are on and flipping all the I/O on and off to surge the power lines. Power is from my laptop USB port.

The top line is the 5V line from the USB port. This is expected to be fairly clean. The scope showed that it was relatively flat with with very little peak to peak action. This shows my laptops 5V line is a relatively good power source for the PDS.

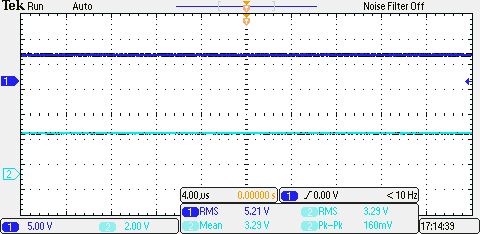

The bottom line is the 3.3V line that is produced from the regulator on the PDS. As you can tell it is not level and oscillates a bit. The peak to peak is at 1.44V which is a very dirty power line. To fix this I added a 1uF capacitor to the 3.3V line which generated the following power signals.

The 3.3V line now has a peak to peak of 160mV which is pretty good. I tried a 10uF capacitor to see if this could be improved but I received the same results. The PDS V1.2 will need to have a 1uF capacitor added to the board before production. This will be added via dead bug technique to the PDS V1.1 boards.