With the cylinder head “rebuilt” its time to install it back on the block. I am using a FEL-PRO HS 8647 PT-1 head gasket set which has all the seals for the top end of this engine.

For head bolts I just reused the original ones. The service manual doesn’t say if I need new ones or not. Of course Porsche 924 forums say you absolutely need new ones :)

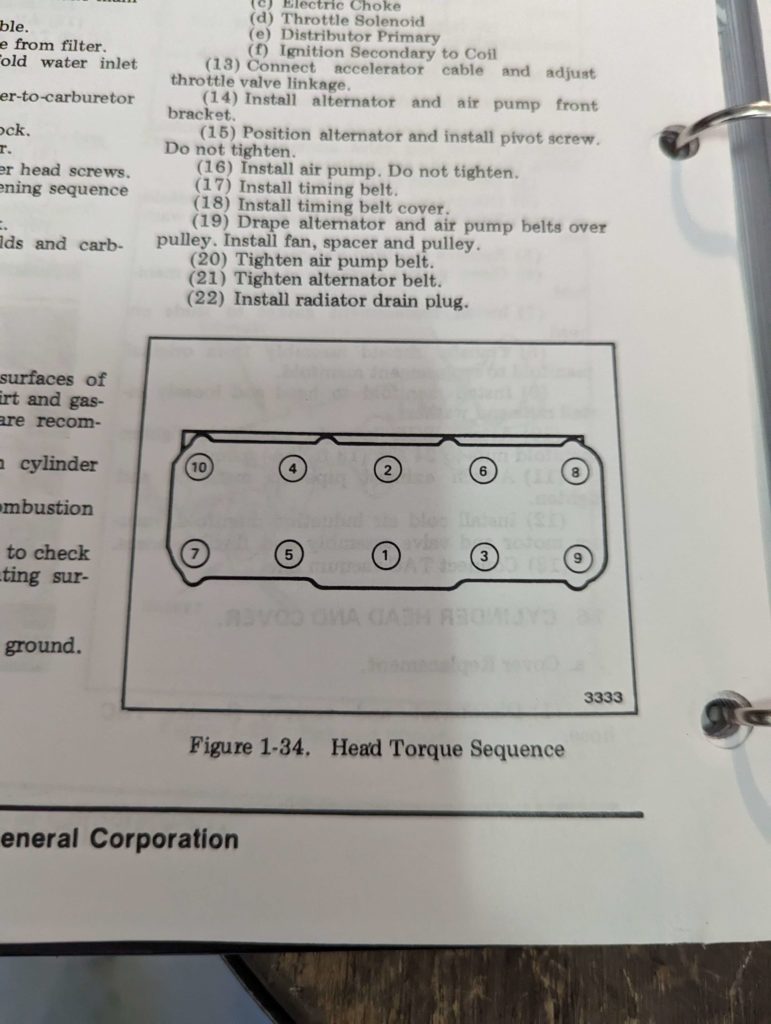

The torque pattern is normal but the engine has a 2-step torque step. You bring the torque of the headbolts up to the first spec, 65 ft-lbs, and then you need to run the engine and heat it up and then retorque the head bolts and bring it up to 85 ft-lbs.

Also, you should set the valve lash at the same time as it is required to bring the engine up to temperature to set the lash correctly. You will need two valve cover gaskets to do this correctly. So order a FEL-PRO VS50175C valve cover gasket set along with the head gasket set.

However at this point, I set the valve lash to 0.007″ on the intake and 0.017″ on the exhaust which is the factory lash for cold.

With the head and accessories installed, I set the timing of the cam gear and cylinder 1 being at top dead center. After checking everything out I tested the compression for each cylinder to see if we improved it.

Compression test:

- 150lbs

- 90lbs

- 85lbs !!!!

- 120lbs

From zero to 85lbs! Now this is no where near what it should be but should make it run better!

The valve cover looks pretty terrible so lets sand blast it and give it some fresh spray paint

It runs! There is a weird oil leak up on the front of the valve cover but it runs and doesn’t backfire. It starts easy as well. I won’t be able to bring it up to temperature yet as I need to get the cooling system working before then.