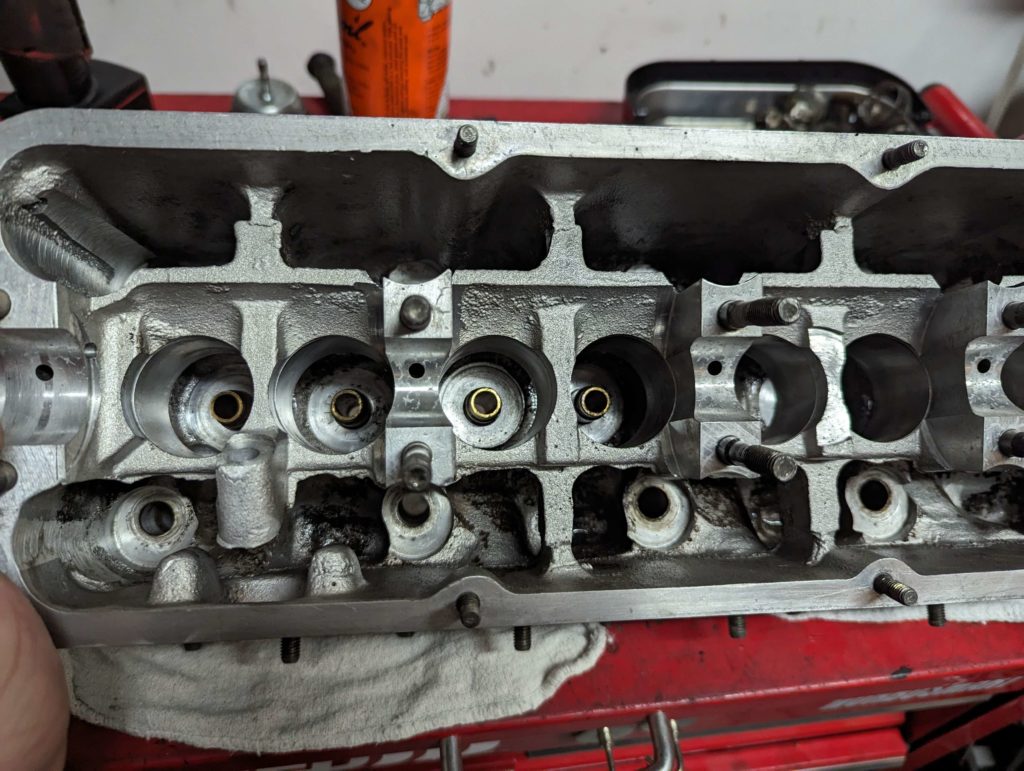

After a couple rotations in the the ultrasonic cleaner the cylinder head cleaned up nice!

Still some stuck on grime down in the oil galleys but this will be perfectly acceptable for getting it running.

What a stark difference between how it started! The ultrasonic cleaner really does a great job.

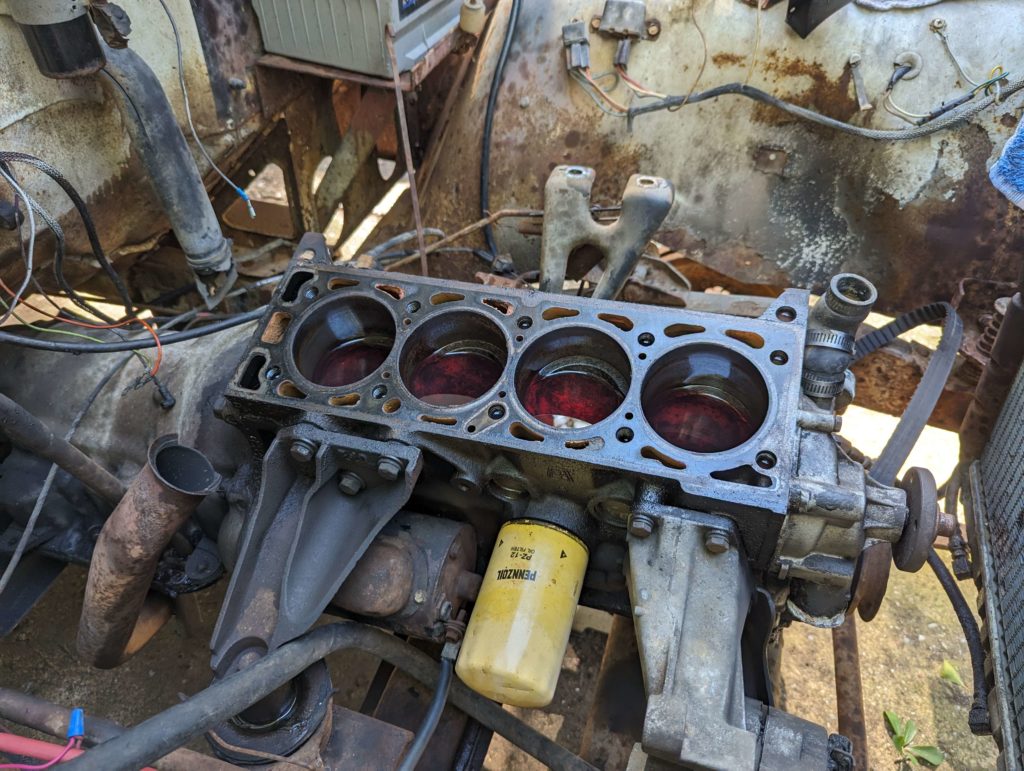

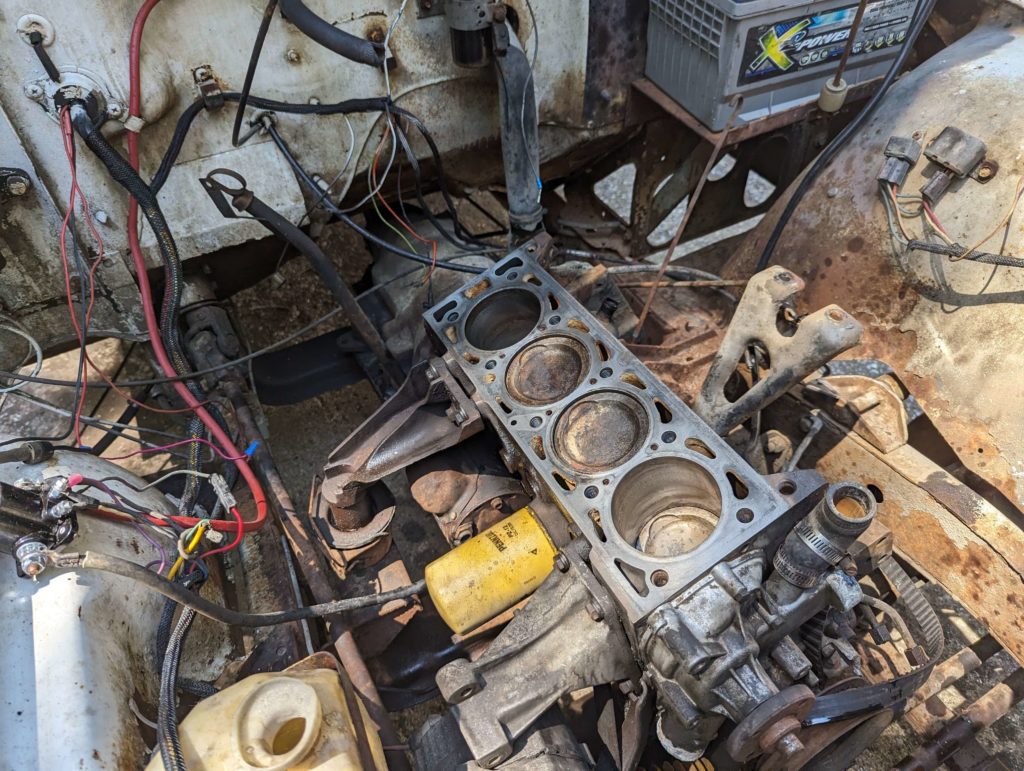

I am not going to mic out and measure this cylinder block. Lets just assume its all good ;)

Just going to give the valves a lap to clean up the valve seats since that is what I think is wrong with cylinder 3.

Some 120 followed by 240 grit valve lapping compound and a power drill made short work of cleaning up the valve seats. I think we may get this engine to run!

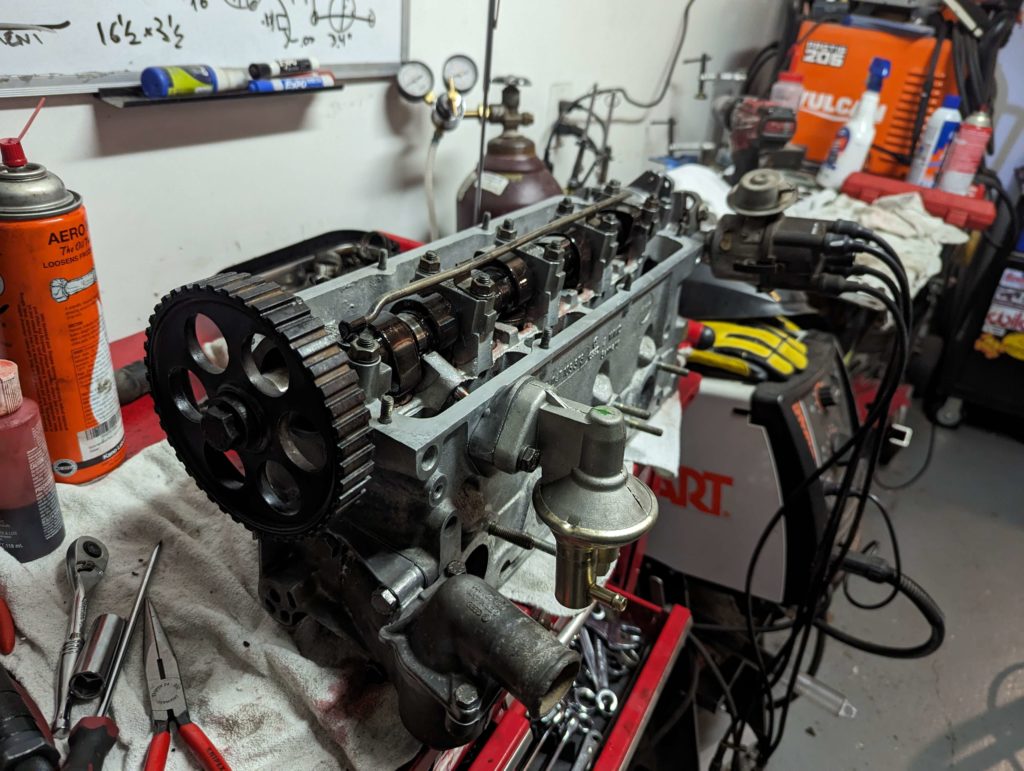

The engine went back together without much fuss. The Factory Service Manual the Jeep came with has this detailed out which made the reassembly smooth. The intake manifold was cleaned up in the ultrasonic cleaner.

When the cylinder block was getting ultrasonic cleaned, I soaked the cylinders in ATF to make sure the rings where loose and unstuck completely.

Then I cleaned up the deck of the block. In cylinder 3 I went after the rust that was deposited on the cylinder walls with scotchbrite. I managed to get most of the rust off. What is interesting about this block is the material. It is called Alusil which is an aluminum / silicon alloy. When they hone the cylinder walls they use a special polishing compound that can wear the aluminum but not the silicon. What is left is cylinder walls that are silicon which is very wear resistant. Should be able to remove the rust off the cylinder walls and leave the silicon walls…. or I wear through the silicon and the 3rd cylinder eats itself :)