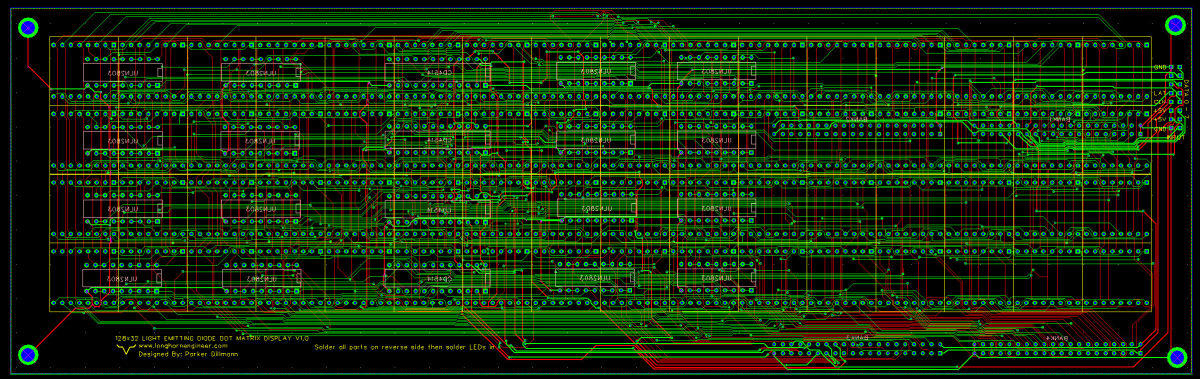

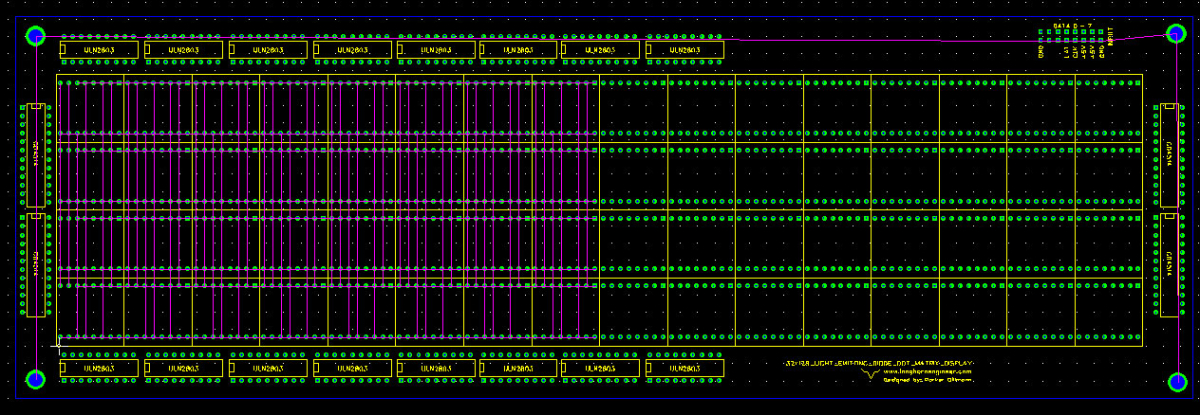

While developing the larger 36×128 DMD I ran out of registers and logic elements in the FPGA I was using. I could have switched to a larger FPGA but that would put the final product out of the price range I was aiming for. FPGAs have loads of dedicated ram so I decided to move the display memory from registers to a chunk of block ram. To test to see if the RAM code works I wrote a program for the 16×96 display in RESET_VECTOR. It took a bit of tweaking as I have never used block ram before but I was able to get it working.

module LED_Matrix_16x96

(

clk,row,col,SDRAM_CS,SRAM_CS,LAT,INPUT,SCLK

);

input wire clk;

input wire LAT;

input wire INPUT;

input wire SCLK;

output reg [0:15] row;

output reg [95:0] col;

output reg [0:0] SDRAM_CS;

output reg [0:0] SRAM_CS;

reg [24:0] clk_slow;

reg [4:0] row_cnt;

reg [1535:0] col_buffer;

reg [3:0] read_addr;

reg [3:0] write_addr;

reg [95:0] disp_mem_data;

reg disp_mem_wren;

wire [95:0] disp_mem_q;

reg [3:0] sel;

initial

begin

row <= 16'b0000000000000001;

col <= 16'b0000000000000000;

SDRAM_CS <= 1'b0;

SRAM_CS <= 1'b0;

clk_slow <= 16'b0000000000000000;

row_cnt <= 5'b00000;

write_addr <= 4'b0000;

read_addr <= 4'b0000;

disp_mem_wren <= 0;

sel <= 4'b0000;

end

always @(posedge clk)

begin

clk_slow <= clk_slow + 1'b1;

if(!LAT & row_cnt == 5'b01111)

begin

case(sel)

4'b0000:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[1535:1440];

sel <= 4'b0001;

end

4'b0001:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[1439:1344];

sel <= 4'b0010;

end

4'b0010:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[1343:1248];

sel <= 4'b0011;

end

4'b0011:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[1247:1152];

sel <= 4'b0100;

end

4'b0100:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[1151:1056];

sel <= 4'b0101;

end

4'b0101:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[1055:960];

sel <= 4'b0110;

end

4'b0110:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[959:864];

sel <= 4'b0111;

end

4'b0111:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[863:768];

sel <= 4'b1000;

end

4'b1000:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[767:672];

sel <= 4'b1001;

end

4'b1001:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[671:576];

sel <= 4'b1010;

end

4'b1010:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[575:480];

sel <= 4'b1011;

end

4'b1011:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[479:384];

sel <= 4'b1100;

end

4'b1100:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[383:288];

sel <= 4'b1101;

end

4'b1101:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[287:192];

sel <= 4'b1110;

end

4'b1110:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[191:96];

sel <= 4'b1111;

end

4'b1111:

begin

write_addr <= sel;

disp_mem_wren <= 1'b1;

disp_mem_data <= col_buffer[95:0];

sel <= 4'b0000;

end

default:

begin

sel <= 4'b0000;

write_addr <= 4'b0000;

disp_mem_wren <= 1'b0;

end

endcase

end

else

begin

disp_mem_wren <= 1'b0;

sel <= 4'b0000;

end

end

always @(posedge clk_slow[10])

begin

if(row_cnt > 5'b01111)

begin

row_cnt <= 5'b00000;

end

col <= disp_mem_q;

row_cnt <= row_cnt + 1'b1;

row <= {row[15],row[0:14]};

read_addr <= read_addr + 1'b1;

end

always @(posedge SCLK)

begin

if(LAT)

begin

col_buffer <= {col_buffer[1534:0],INPUT};

end

end

display_ram disp_mem_inst (

.rdaddress (read_addr),

.wraddress (write_addr),

.clock (clk),

.data (disp_mem_data),

.wren (disp_mem_wren),

.q (disp_mem_q)

);

endmodule