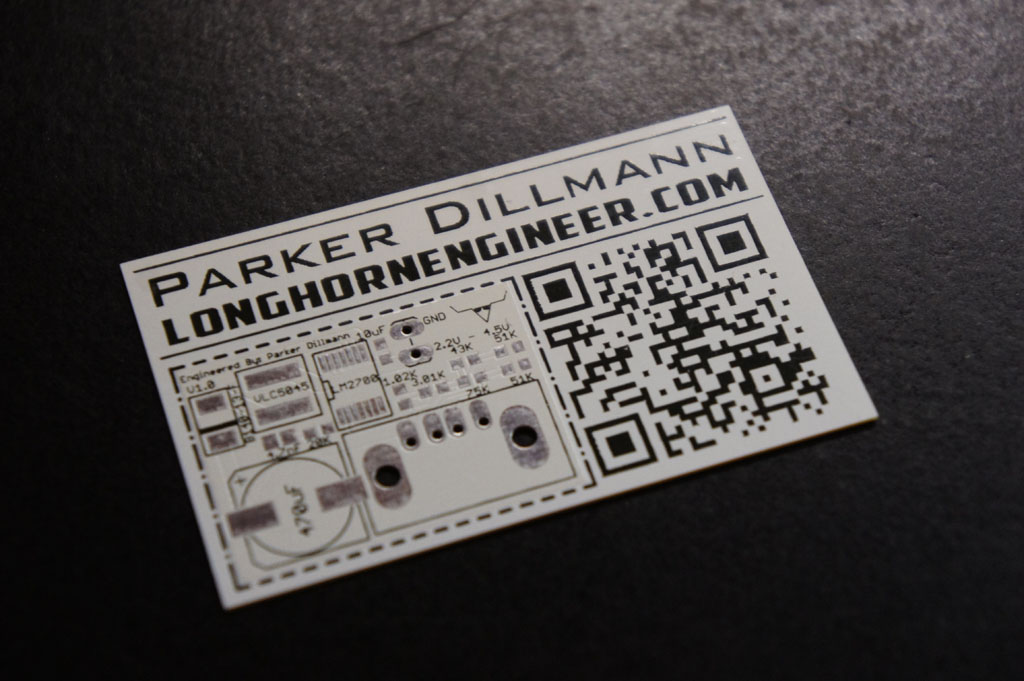

This is the how to page on how to build the SUPER BOOST pcb. Please refer to the disclaimer first. For hobby use only. This design is completely open source. Check the Super Boost project page for the file downloads.

Since the board contains almost only SMD parts you should be familiar in soldering them. If not SparkFun has a really nice SMD soldering guide.

You will need the following parts.

Bill of Materials

Name: MFG P/N: Mouser P/N: QTY:

U1 LM2700MT-ADJ/NOPB 926-LM2700MT-ADJNOPB 1

L1 VLC5045T-100M 810-VLC5045T-100M 1

D1 B130-13-F 621-B130-F 1

C1 C1608X5R1A106MT 810-C1608X5R1A106M 1

C2 CC0805KRX7R9BB472 603-CC805KRX7R9BB472 1

C3 UCL1A471MCL6GS 647-UCL1A471MCL6GS 1

R1 CRCW060320K0FKEA 71-CRCW0603-20K-E3 1

R2 CRCW06033K01FKEB 71-CRCW06033K01FKEB 1

R3 CRCW06031K02FKEA 71-CRCW0603-1.02K-E3 1

R4 CRCW060375K0FKEA 71-CRCW0603-75K-E3 1

R5 CRCW060343K0FKEA 71-CRCW0603-43K-E3 1

R6, R7 CRCW060351K0FKEA 71-CRCW0603-51K-E3 2

USB Plug 87520-0010BLF 649-87520-0010BLF 1

Bill of Material list on Mouser

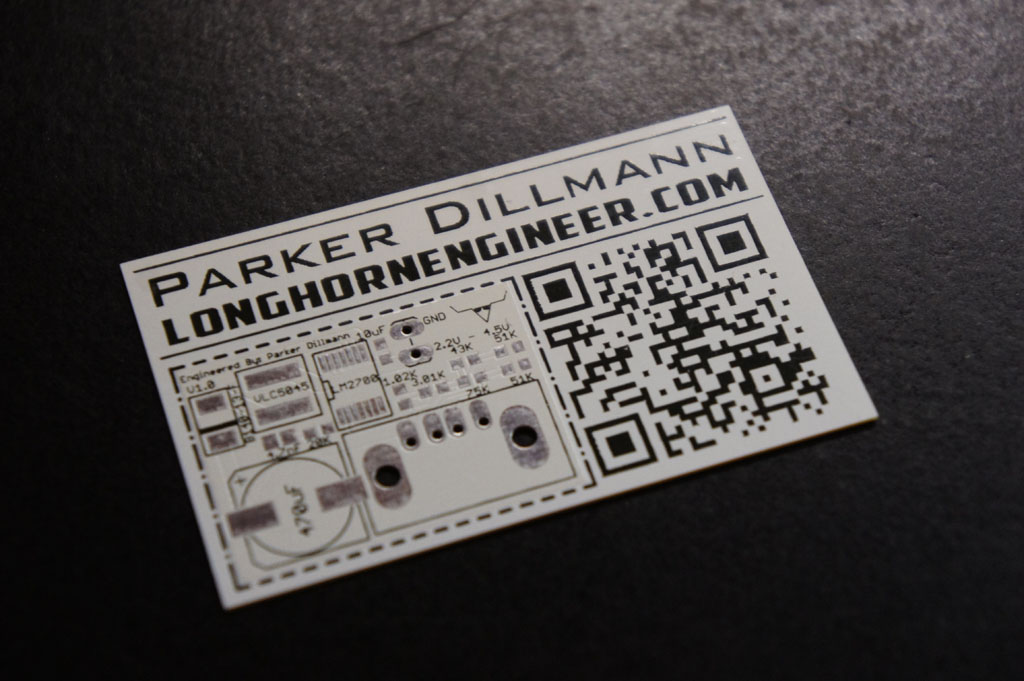

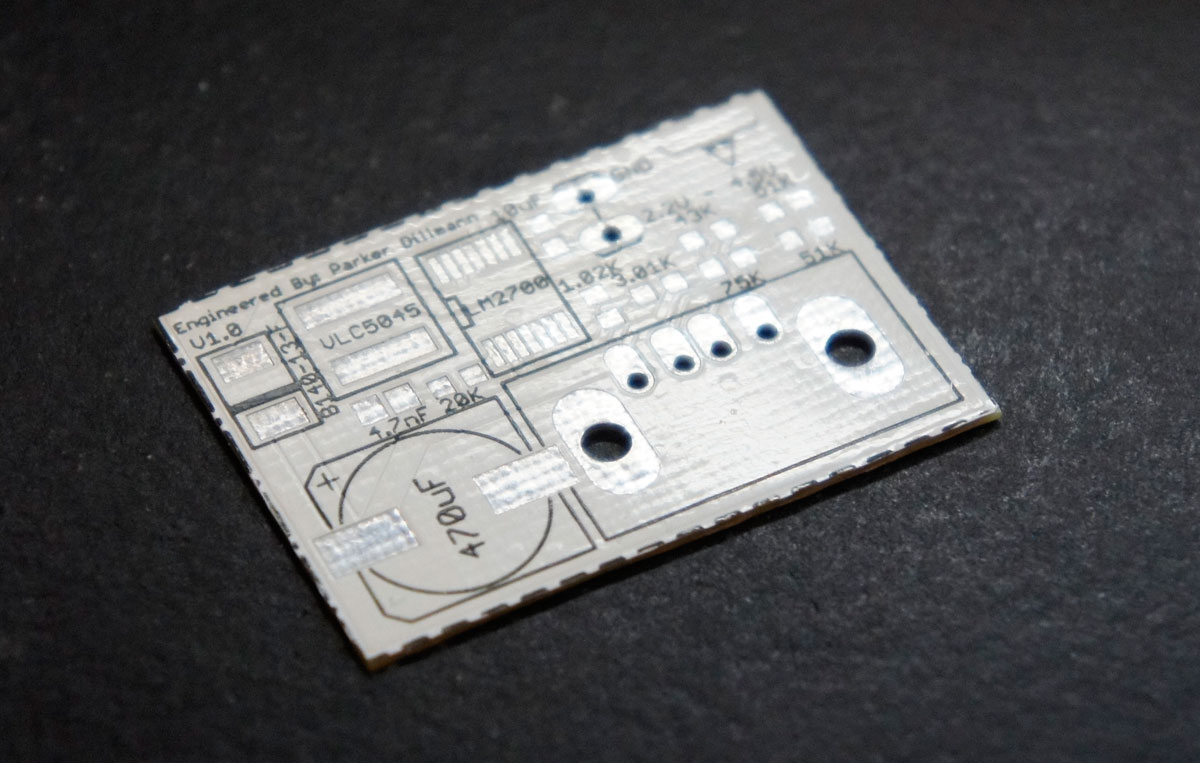

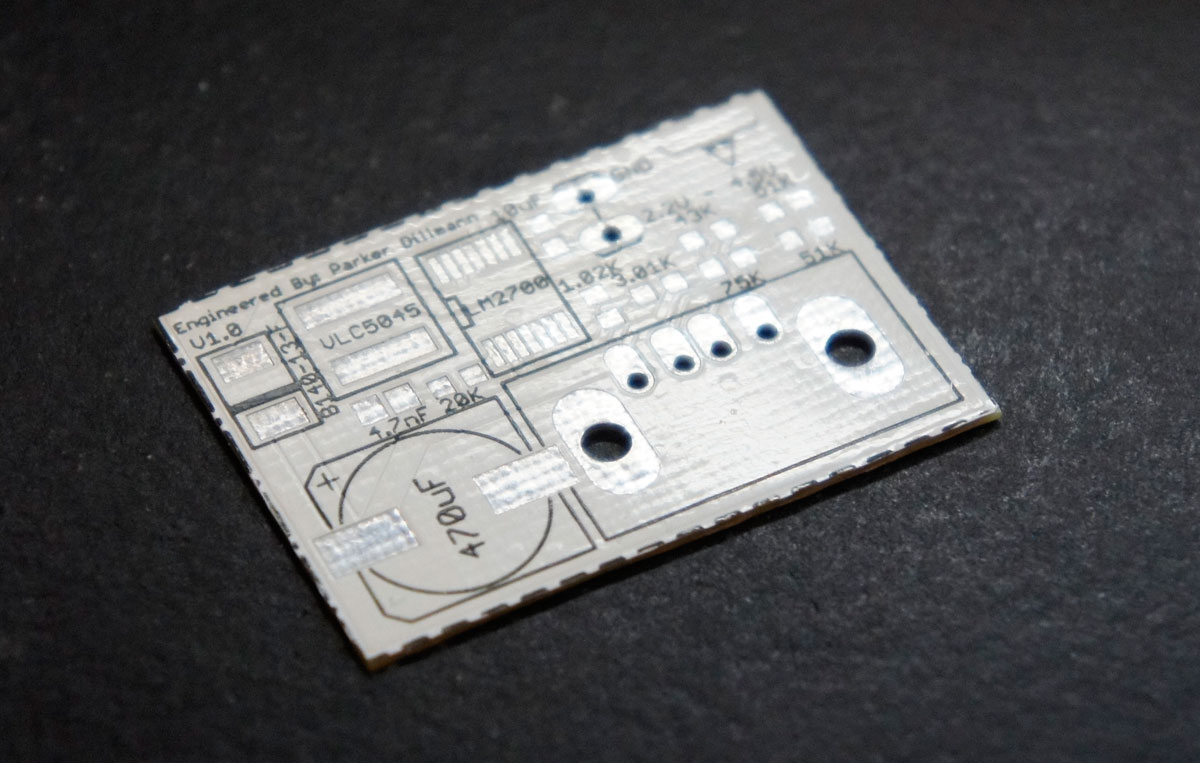

If you received the PCB on a business card you can cut the PCB out around the dotted lines or leave it as is.

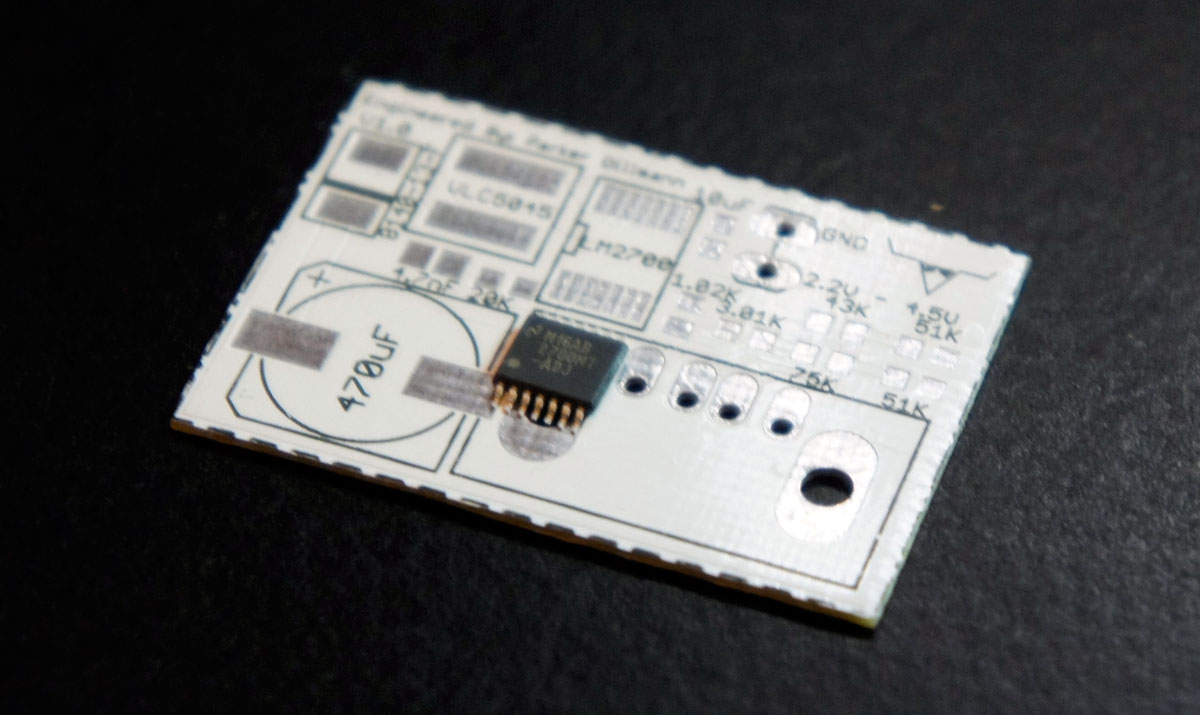

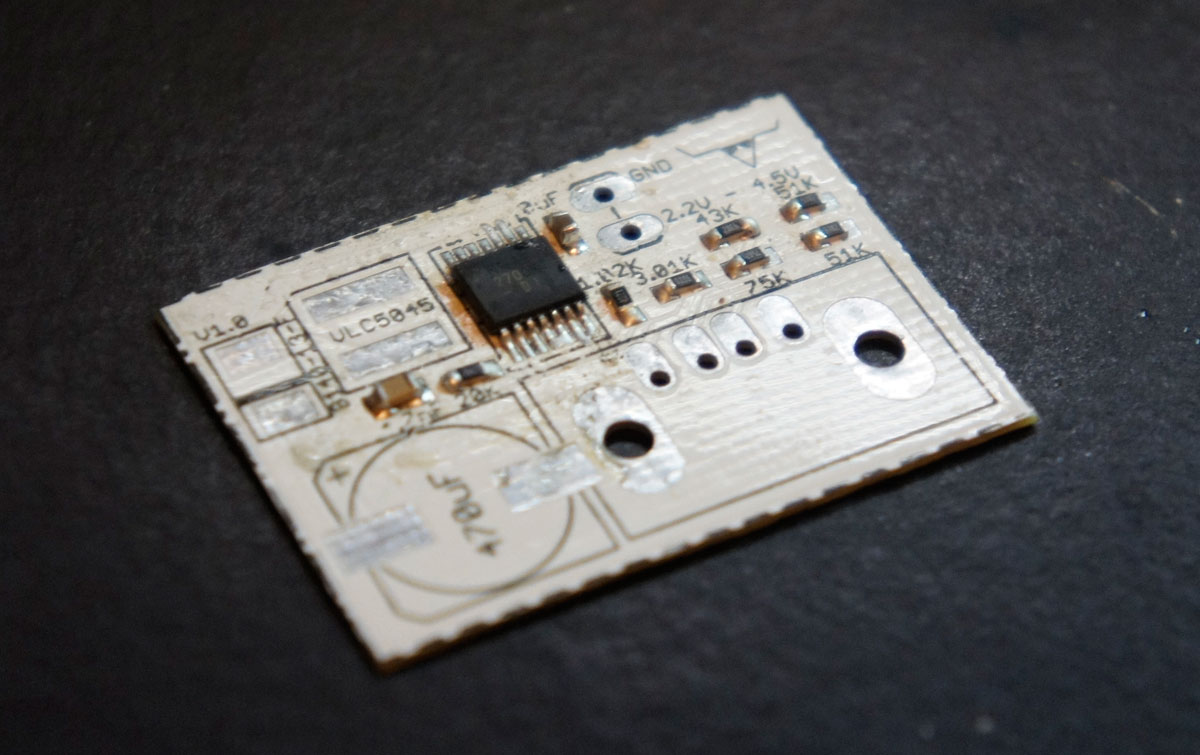

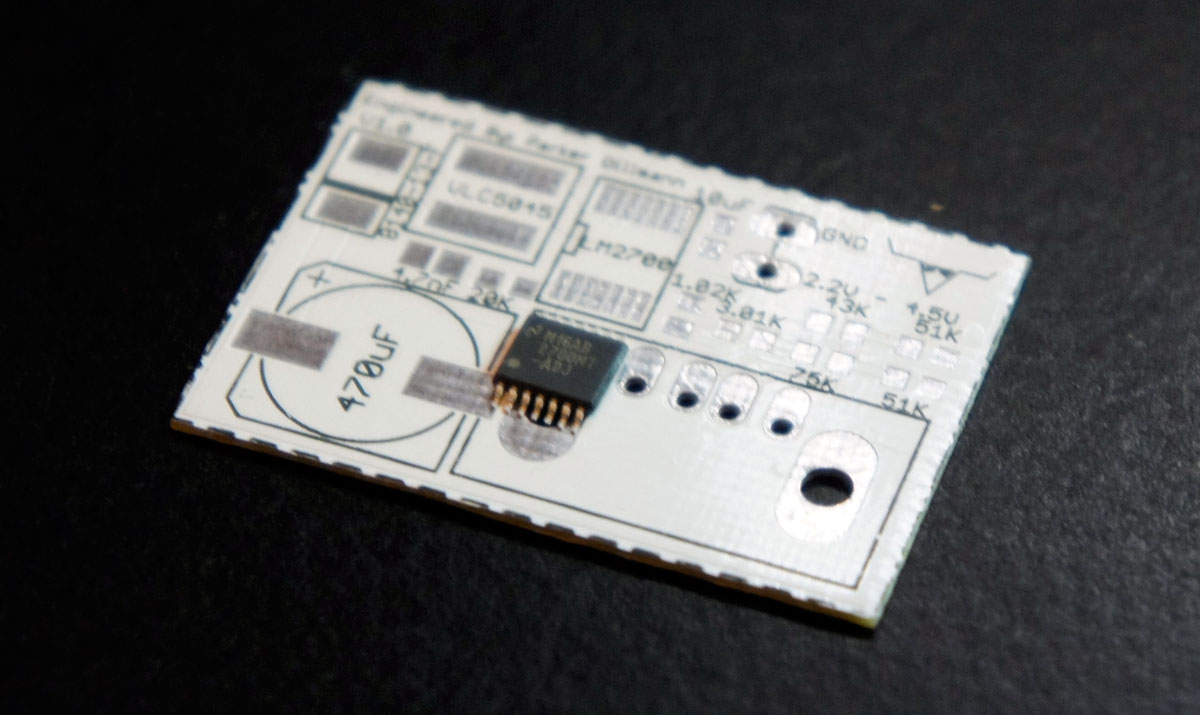

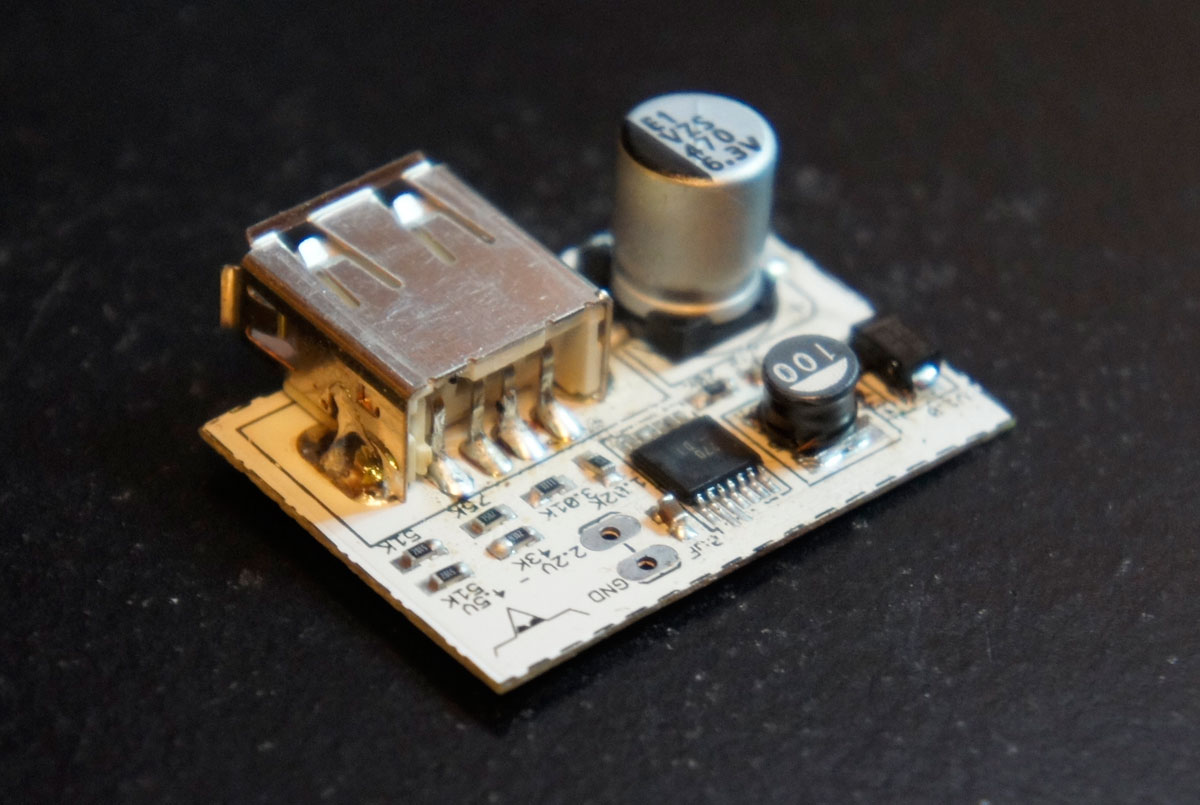

Start by tacking the LM2700 chip down with a soldering iron in a single corner.

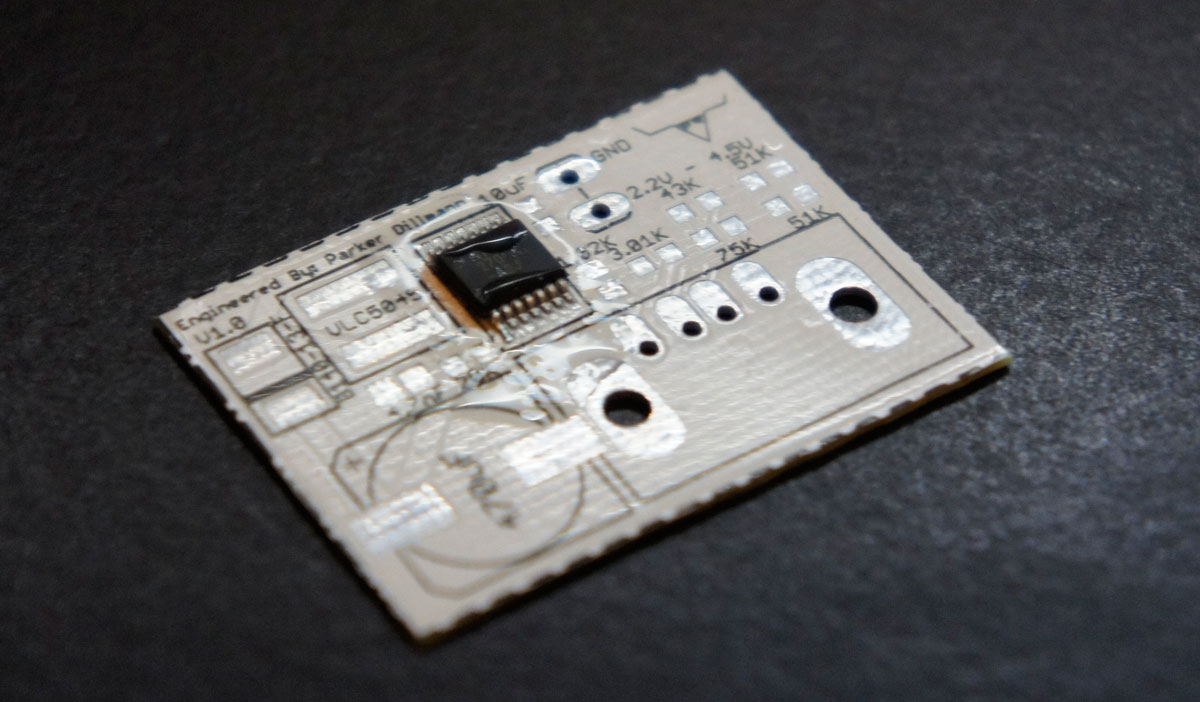

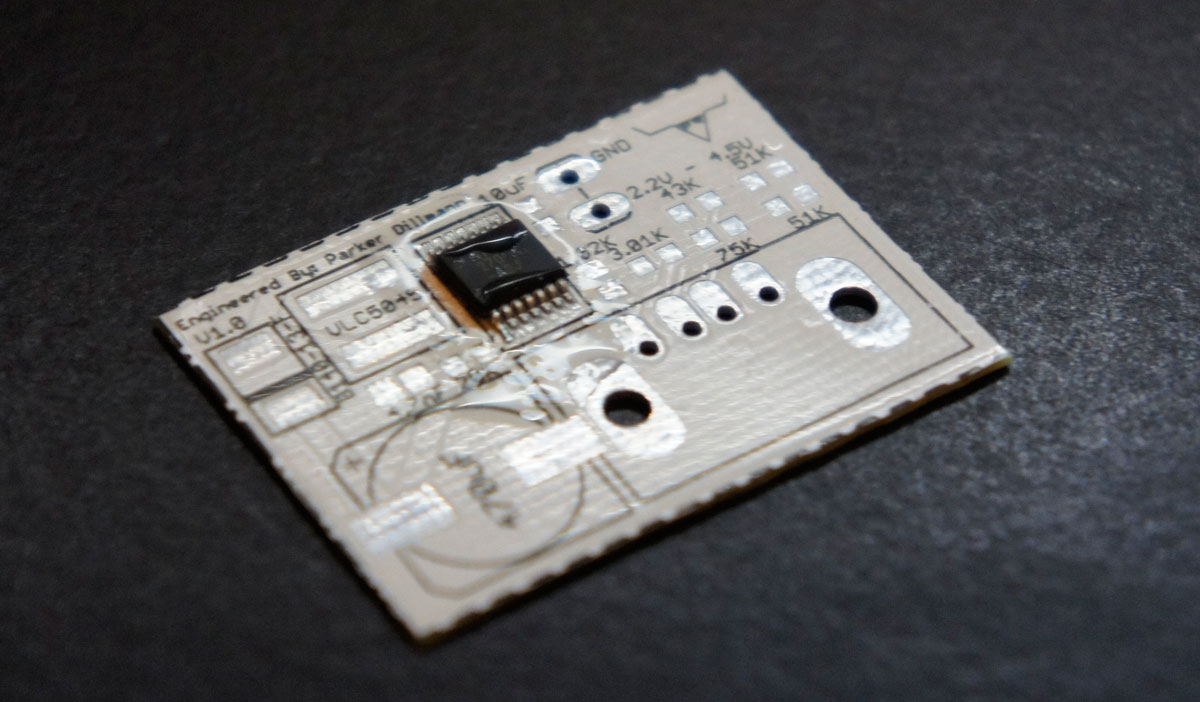

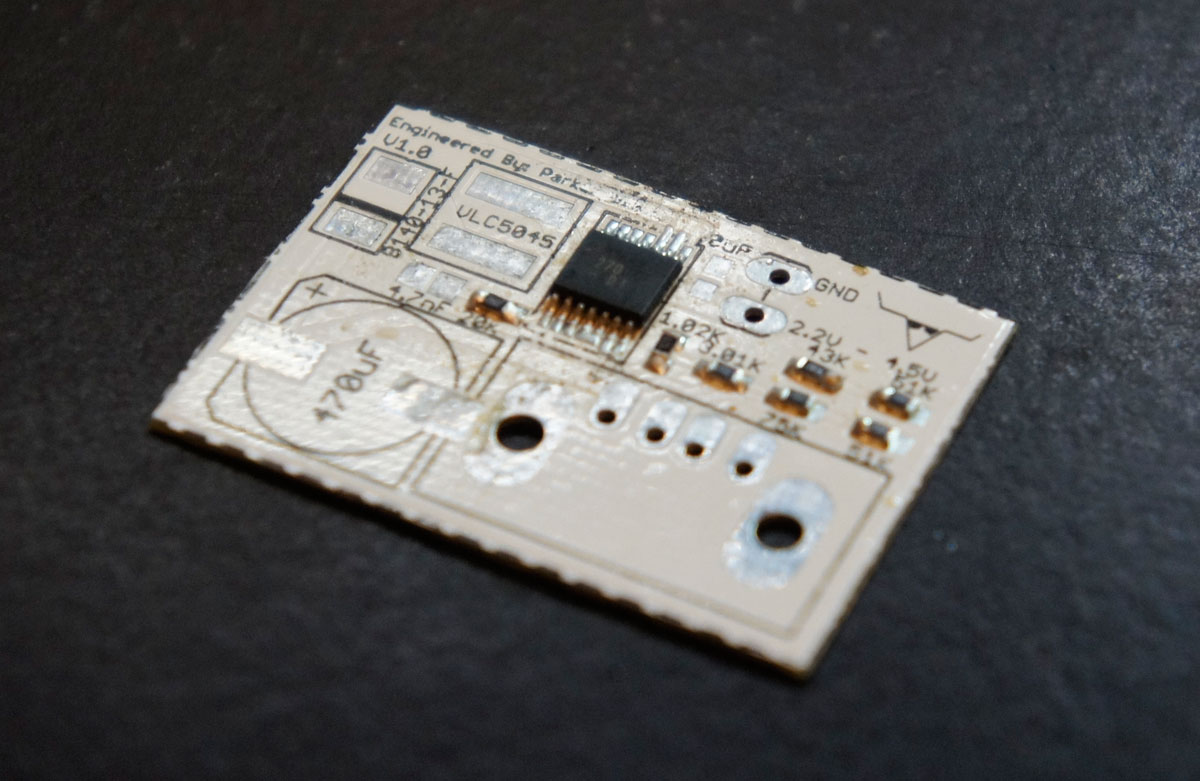

I usually tack down the pin 1 on the chip then apply some flux then finish the chip. After soldering the LM2700 down solder the resistors down.

Then the two small SMD capacitors.

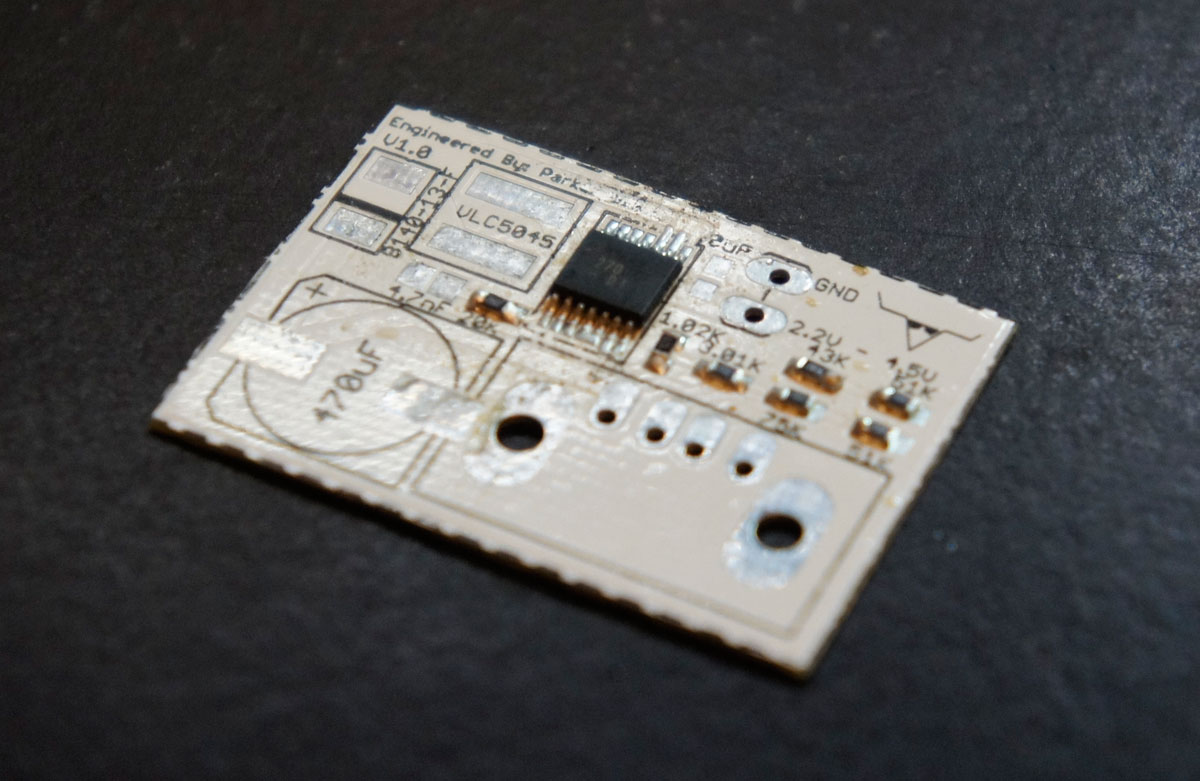

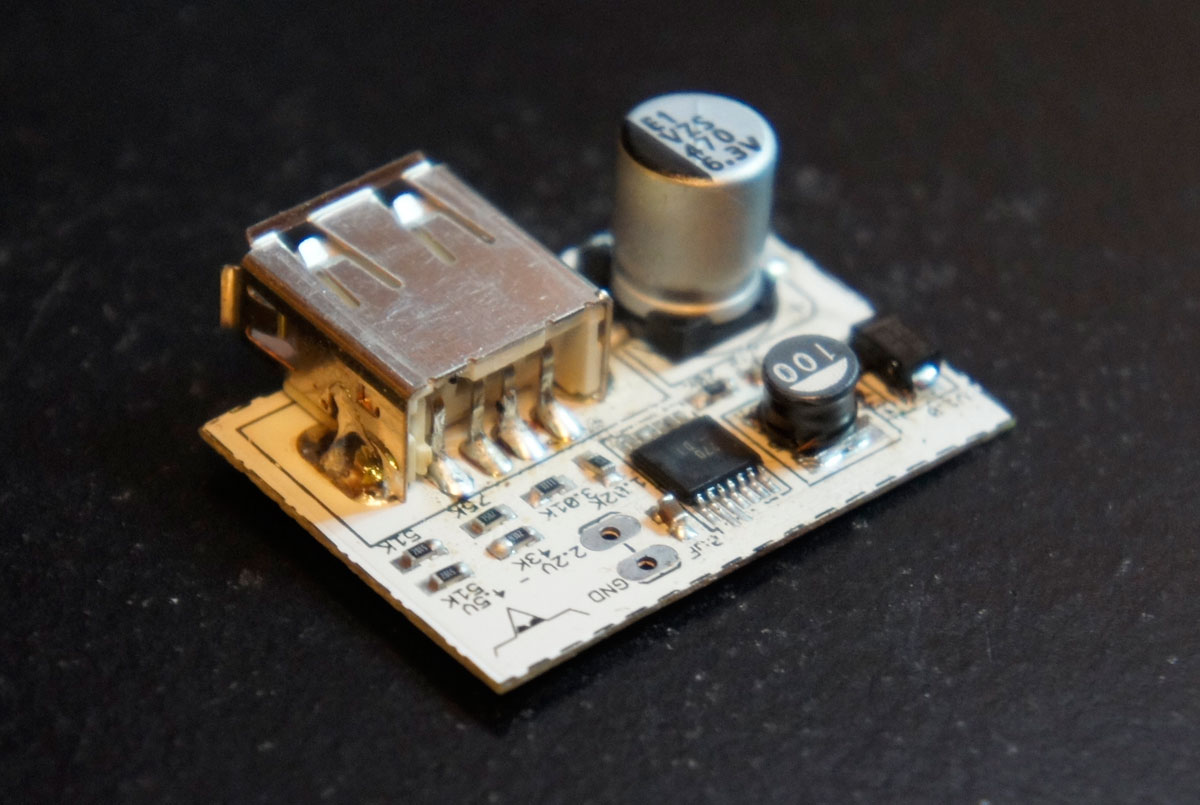

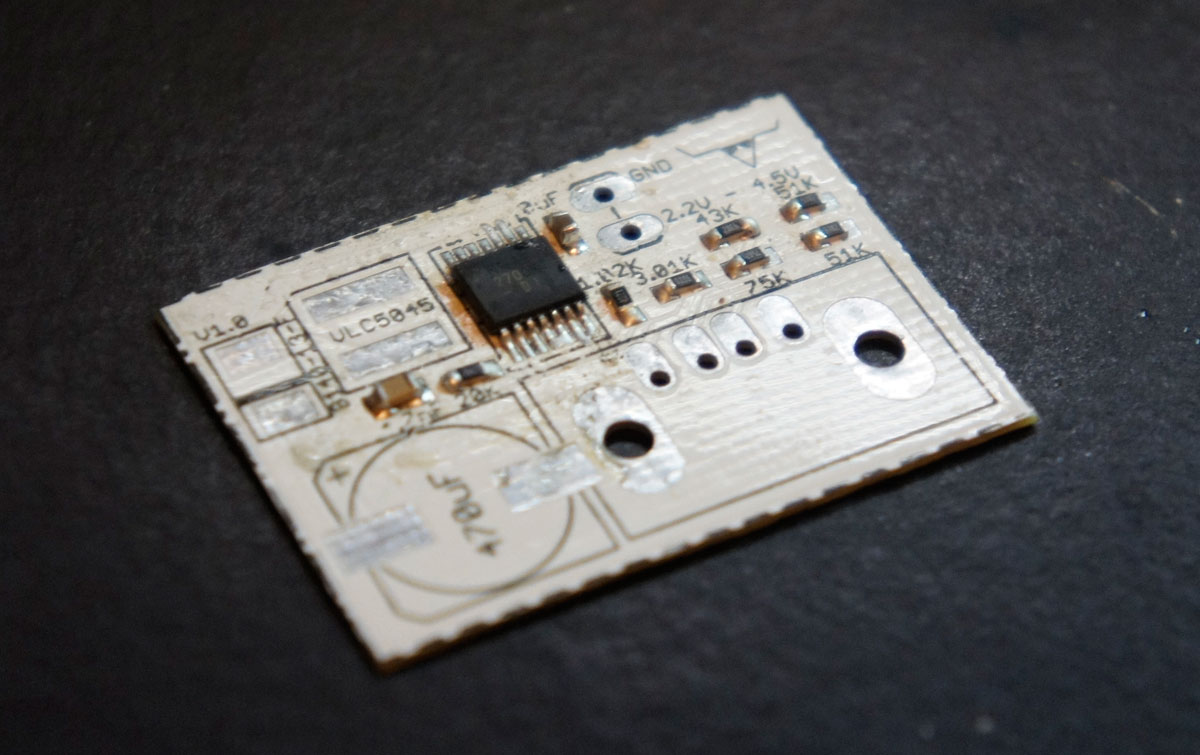

The inductor, diode, and large 470uF capacitor should be soldered next. The inductor is non polarized but care should be taken with the 470uF cap and diode to make sure they are originated correctly.

The USB port is the last thing to install. Before connecting your device to charge it use a multimeter and verify that 5V is across the 470uF capacitor terminals.

Success! Android phone charging. It is charging at a steady rate of 750mA.