After chatting with Stephen Kraig on the podcast about hacking tig foot control pedals, I wondered what made the Vulcan brand foot pedal different. Most tig welding machines have either a 5 pin or 6 pin connector. Both of these types of foot pedals work the same. There is a simple SPST switch and then a potentiometer for how far the pedal travels. Farther the pedal goes down, the more amperage the tig welder will output. This requires 5 wires. The 6 pin connectors just have an unused pin.

The Vulcan Tig Welder (from Harbor Freight) has a 9 pin connector for the foot pedal! What do these extra pins do? Or are they just unused as well?

The connector is a Weipu SP21 series. Part Number: SP2110/P9 II 1. Looks like you can get these on AliExpress.

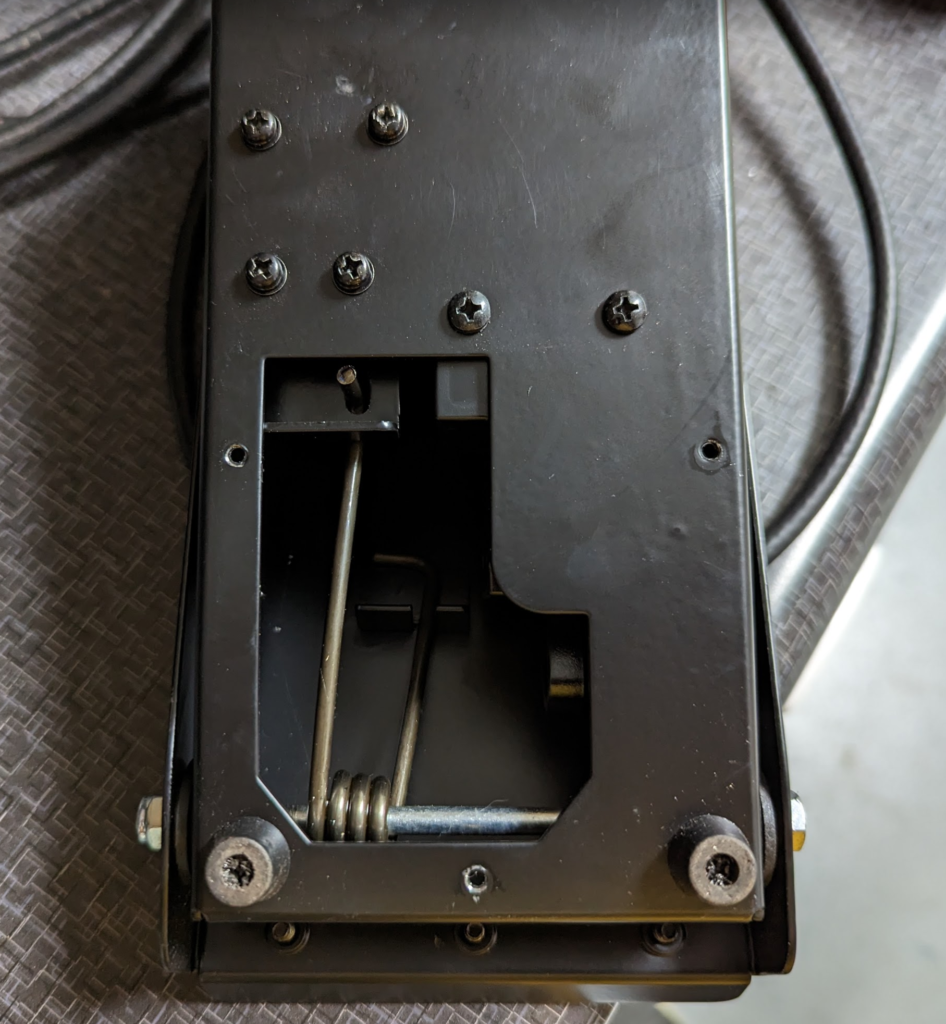

To open the foot pedal you need to remove this the panel on the bottom side with 3 screws. You will see the foot pedal spring inside.

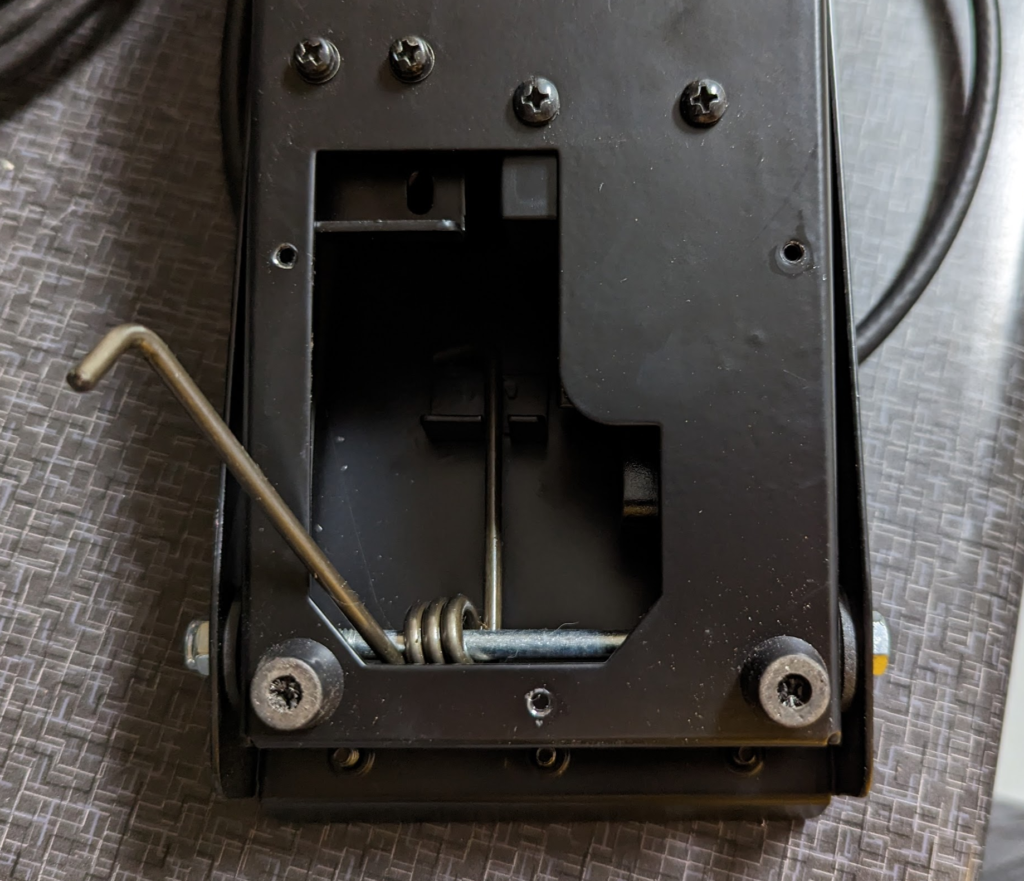

The spring needs to be pressed down and unhooked from the bottom side (side facing upwards during disassembly).

Then use a 10mm socket and wrench to remove the bolt used for the pivot and pull the case apart. There are two spacers on the bolt that locate the top part of the foot pedal with the bottom side along the pivot bolt.

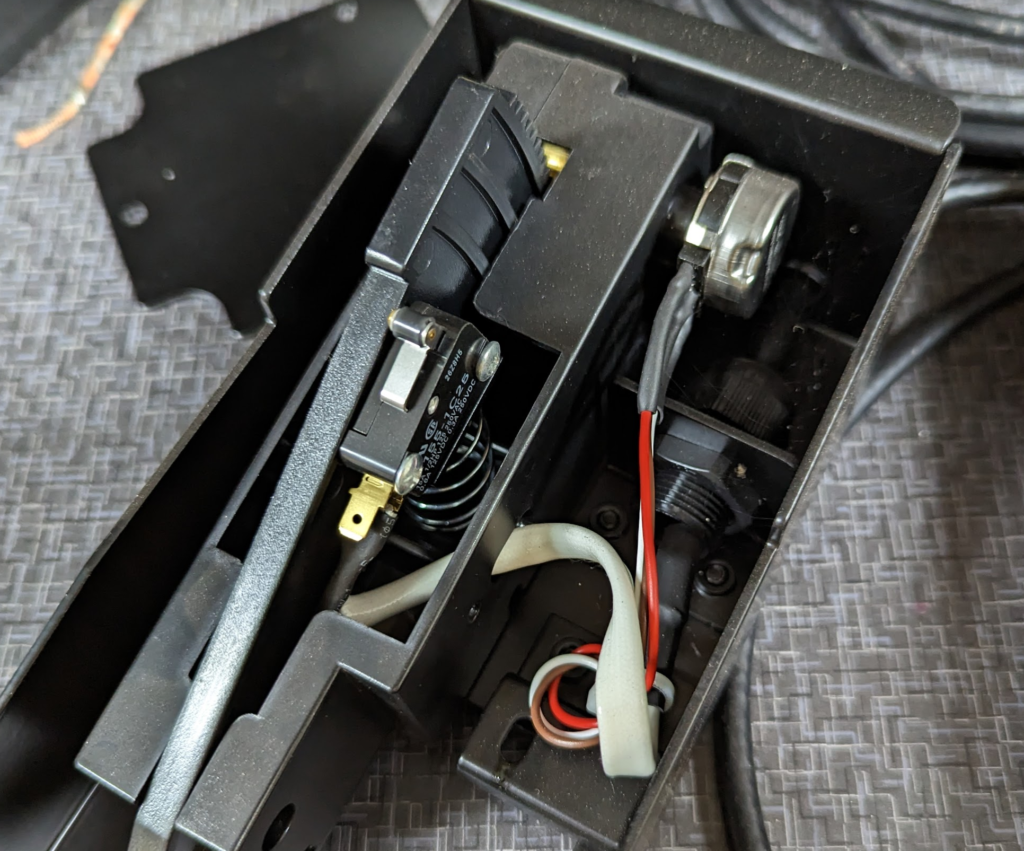

Inside the pedal we have a microswitch and a single potentiometer. Only 5 wires. Why Vulcan specified a 9 pin connector is lost to me. Would be interesting to see if there are any connections to the other 4 “unused” pins on the welder side…

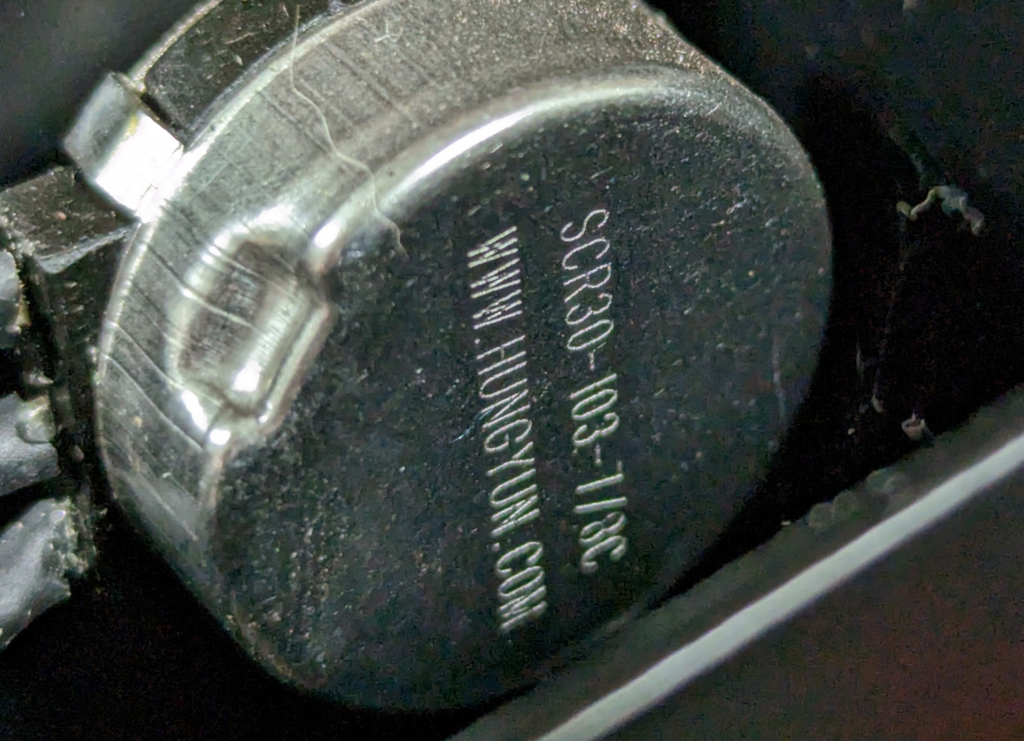

Potentiometer is a SCR30-103-7/8C by HungYun. 10K resistance.

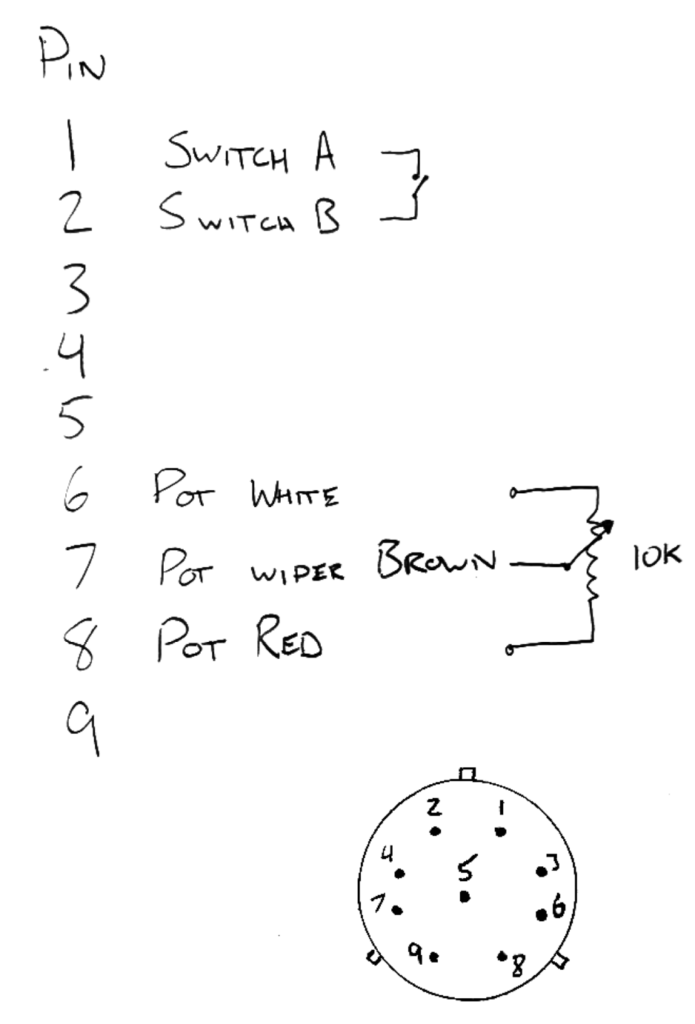

Here is a pinout for the connector.

I can probably get any finger controlled switch to work with this welder if its a 10K potentiometer.