Pulled the gas tank from the Checker. It has rust pin holes and is in rough shape. Original or NOS (new old stock) are really expensive so lets try to save the original.

Pulled the tank and removed the sending unit which had a cork float! The tank looks like it had some damage from a road hazard strike near the original fuel pickup so we will need to repair that as well.

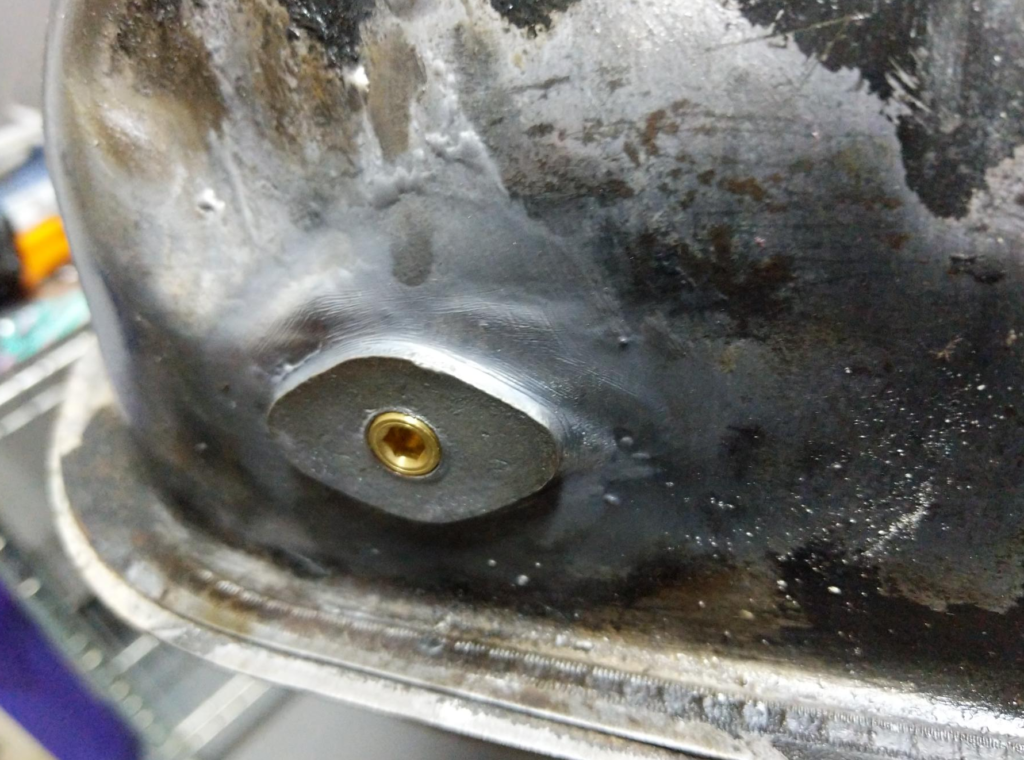

Repairing the bulk of the pin holes was done be flowing leaded solder into them. The above picture is the factory drain that was in the tank where most of the pin holes where located at. The tank is made out of pressed steel that was then soldered/brazed together with lead. Repairing with lead is the “obvious” choice. Use lots of acid based flux!

The original fuel pickup was torn off the tank. I used the lead solder to reattach it. I am not going to use the original fuel pickup so I put a 1/4″ NPT plug into the hole.

After all the repairs where done, I de-rusted the tank with muriatic acid and rinsed with a metal prep (mastercoat metal prep). Before I can epoxy coat the inside of the tank, it needs to be super dry. Hair dryer in the tanks intake tube works like a treat.

Jumping ahead a bit…

Painted the tank with Steel-It stainless paint after removing most of the exterior cruft with a brass wire wheel. I then welded in a backing ring for an in tank fuel pump module from Tanks Inc.

What the tank looks like now. The insides are coated with POR15 tank liner. Hope it lasts!