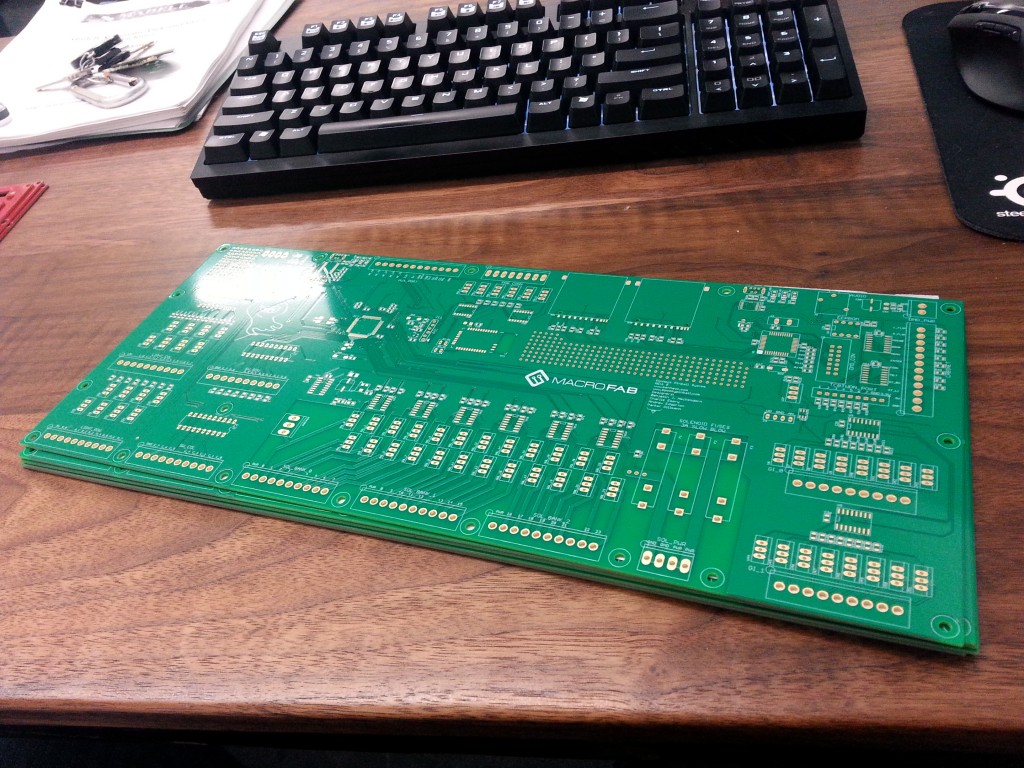

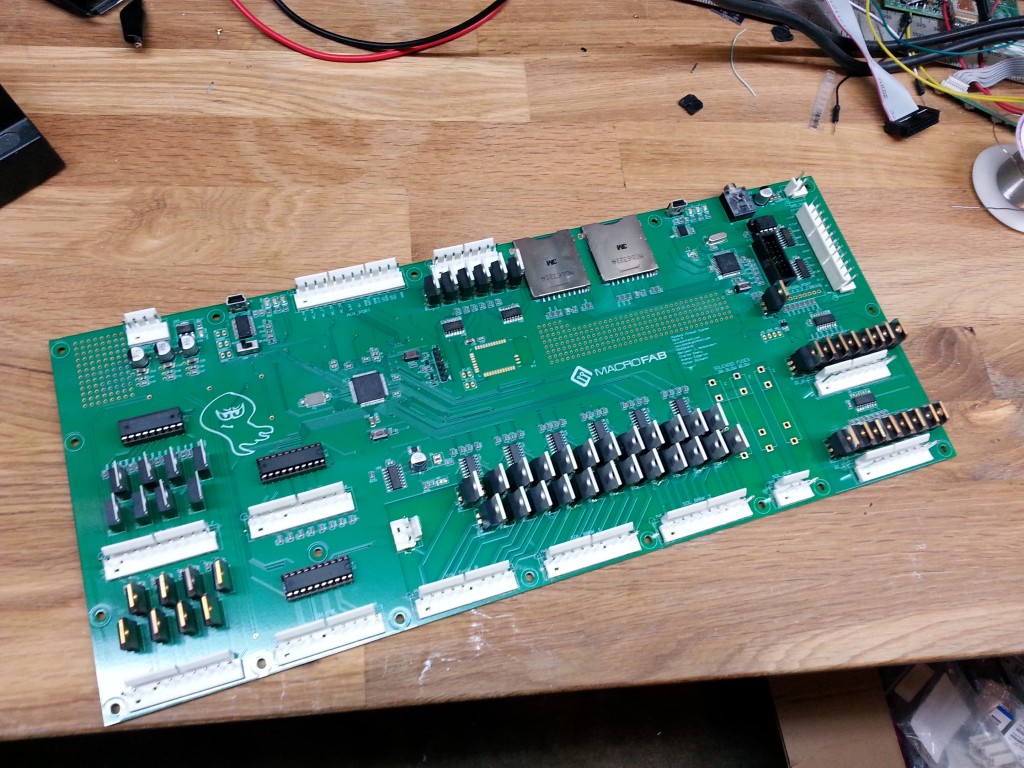

These are the first 5 test boards to make sure the changes from the REV4 board we done correctly. Since I am pretty sure this is the final revision I ordered the boards on FR4 170TG and ENIG finish. 170TG is higher temperature rated substrate which allows for lead free reflow without scotching the board. ENIG finish is a higher quality finish for the pads over HASL as it tends to be flatter and more consistent which is nicer on the pick and place machines.

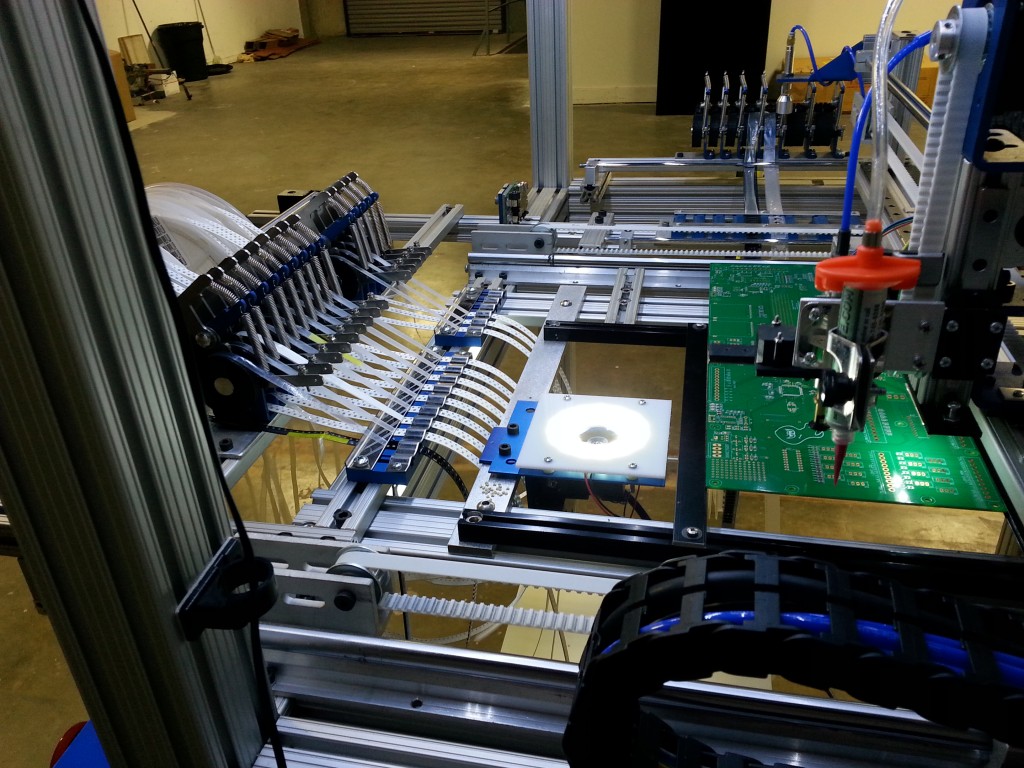

Pinheck board on the pick and place. Currently the machine is only setup to place the passive parts which are the resistors, capacitors, and LEDs. This consists almost 90% of the board parts.

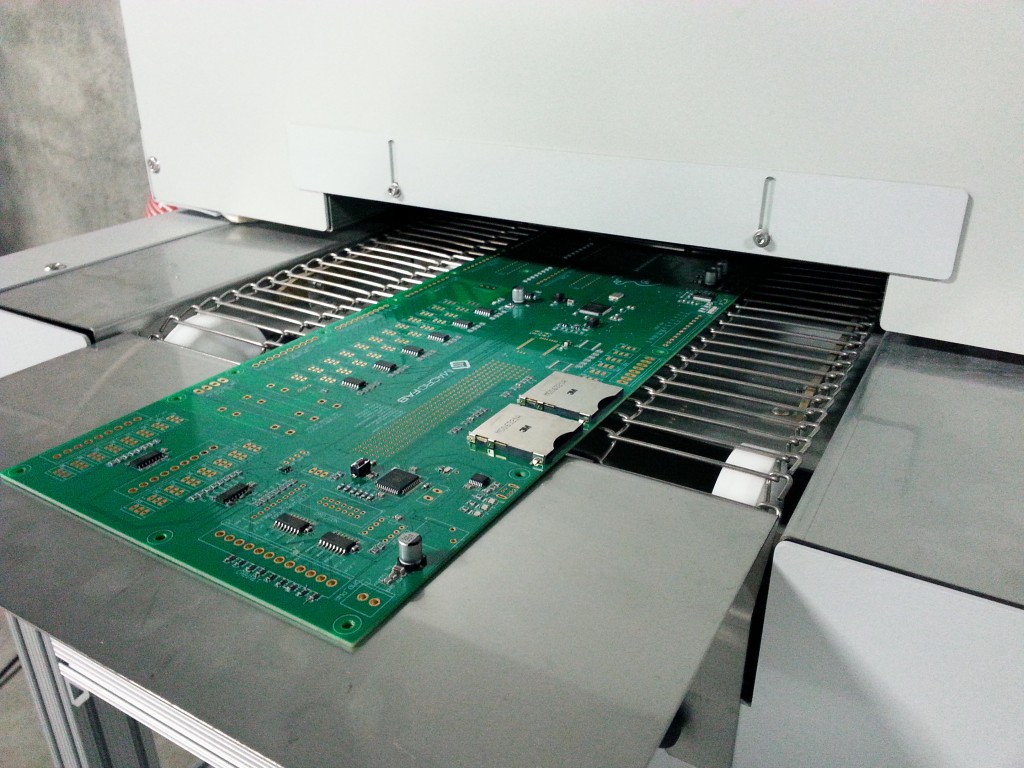

After the pick and place I manually placed the IC chips and placed it on the intake side of our reflow oven.

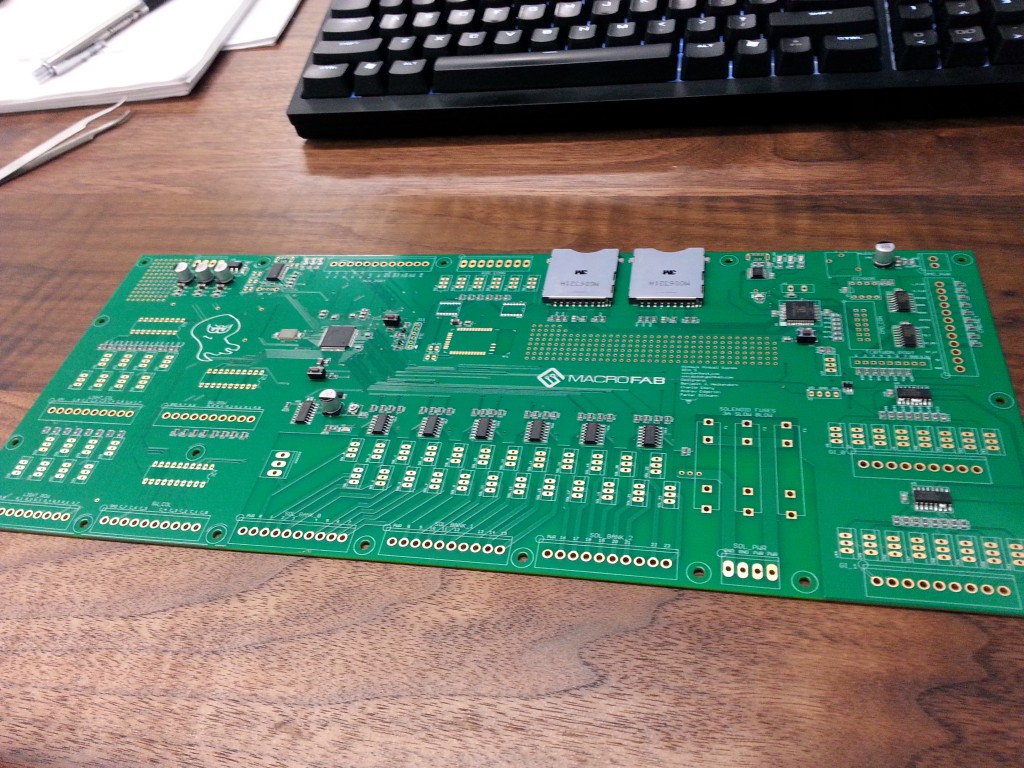

This is what the board looks like after coming out of the reflow. There are a couple bridges on the ICs so I will need to tweak my automatic paste dispenser settings.

Finished soldering the through hole parts. Wishing I had a selective soldering machine about now!